From Lab to Road

What happens when three innovation leaders join forces? The answer is now being tested on the streets of the greater Munich area.

BMW Group has begun road-testing a BMW i7 equipped with large-format solid-state battery (SSB) cells developed by Solid Power, Inc.. These cells feature Umicore’s proprietary cathode active materials (CAM), developed under a joint development agreement with Solid Power.

Driving Innovation Through Partnerships

Solid-state batteries use a solid electrolyte instead of the traditional liquid one, offering improved safety, efficiency, and energy density. Umicore is at the forefront of cathode materials for SSBs development, moving from laboratory experiments to real-world applications.

For the integration of its advanced cathode materials into next-gen battery cells, Umicore joined forces with Solid Power, an industry-leading developer of all-solid-state battery technology. This collaboration has supported Solid Power’s development of the ASSB cells that are featured in the BMW i7 test vehicle.

Solid-state battery pack design for electric vehicles (EV) concept, new research and development batteries with solid electrolyte energy storage for future car industry, 3d Illustration

Real-World Testing in Munich

BMW Group is playing a pivotal role in validating this technology. A BMW i7 demo vehicle equipped with these advanced batteries is currently undergoing testing on the roads of Munich to assess the performance of SSBs under real driving conditions.

This milestone reinforces Umicore’s strategy: partner early, co-develop with leaders, and scale with purpose. As the SSB market matures, Umicore is positioned to lead with differentiated materials and deep integration know-how.

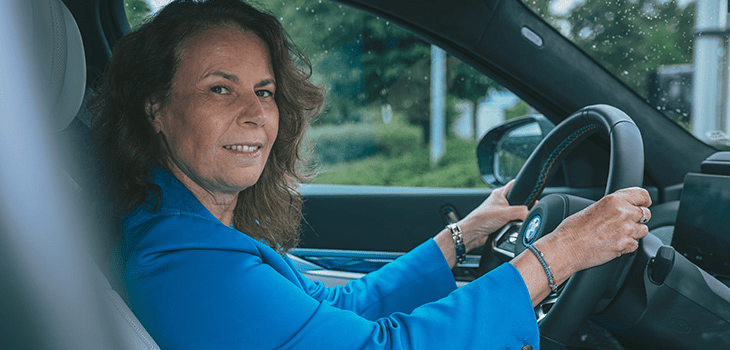

Together with BMW Group and Solid Power, we are pushing the boundaries of battery performance. By surpassing the limitations of conventional lithium-ion batteries, SSBs offer a promising path toward improved performance, reliability, and sustainability in electric mobility.

Karena Cancilleri, EVP Battery Cathode Materials at Umicore.

Karena Cancilleri, EVP Battery Cathode Materials at Umicore, drives the BMWi7 demo car, one of the first all-solid-state battery car that gets tested on the road, in Munich.

Karena Cancilleri, EVP Battery Cathode Materials at Umicore, drives the BMWi7 demo car, one of the first all-solid-state battery car that gets tested on the road, in Munich.

Martin Schuster, Vice President Battery Cell and Cell Module at the BMW Group, says: “Our BMW i7 ASSB test vehicle on the road is a perfect example of the BMW Group's technology-open mindset. We are continuously advancing the development of new battery cell technologies and are constantly expanding our know-how with valuable partners.”

Berislav Blizanac, EVP Cell Technologies at Solid Power, Inc. (Nasdaq: SLDP) said: “BMW's introduction of the i7 test vehicle powered by our cells and solid-state battery technology marks an exciting moment for ASSBs, and we are proud of our role in this achievement.”

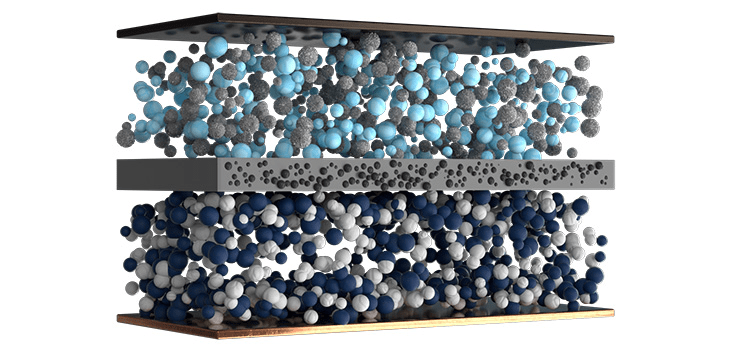

This diagram illustrates the structure of a certain type of Solid State Battery, with a composite layer of cathode active materials and solid electrolyte on top, a separator layer in the center and a composite layer of anode active material and solid electrolyte at the bottom.